Ernest to the Rescue: When Pallets Go Oo La La

May 14, 2015

The Problem

Ton Savon, a leading manufacturer of private label bath and beauty products from the South of France, experienced a successful launch of soaps sold at Costco. When it was ready to pitch Costco with a new French hand cream, Ton Savon recruited Ernest Packaging Solutions.

The two companies had worked together on a packaging solution nearly a decade prior to this new launch. Ton Savon knew Ernest could engineer the right shipping and merchandising solution to win over Costco again.

“Costco has very strict standards for how its products are delivered, packed and shipped to stores,” Vincent Elhaik, Ton Savon owner, said. “The packaging has to be protective and it also has to be good looking. We need to make sure we’re able to marry these two aspects.”

After a successful pitch to Costco, Ton Savon needed to fulfill a pilot-sized order for the holiday season: 20 pallets to be shipped and sold in three to four stores. Ernest got to work right away to engineer a packaging solution to make Costco say, “Oo la la,” to the French hand cream.

“The shipping packaging becomes the merchandising packaging,” Ryan Boring, Ernest Customer Relationship Manager in Los Angeles, explained. “It has to not only protect the product in transit but also function at the point of sale.”

The Ernest Solution

Boring teamed up with Dr. Gary Chao, Ernest’s corrugated marketing manager, to tackle the many functions this packaging had to perform. Because multiple layers went into one pallet, Ernest need to engineer the best possible corrugated construction.

“We don’t want any of the product to take the weight of the other layers,” Boring said. “We take weight into consideration for how much the corrugated can take.”

That’s where Dr. Chao really shines. Have you seen him share his excitement for all things corrugated in our Ernest Edge video?

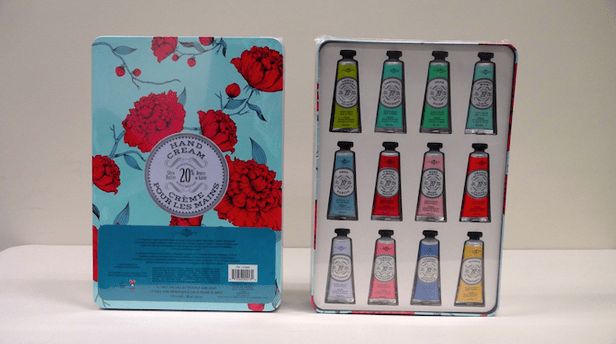

Ton Savon’s hand creams came in a beautiful tin, so Dr. Chao started to construct side slope trays to position the product facing out. Each sound tray could hold six Ton Savon tins.

Then came the task of engineering the layering logistics of the pallets, which hold 10 trays per layer with three layers total. Ernest’s original design for the individual trays was slightly unstable for the tins. Going back the drawing board, Ernest engineered new dividers to keep these tins standing strong.

“The dividers were originally separate pieces and then extended the the overall pallet dimensions too long,” Boring explained. “The new design has all of the pieces coming from the same die cut, and the dividers come through the tray as one whole piece. This also makes it easier on Costco for removal once the product is sold.”

Outside of the trays had a corrugated double shroud to protect the actual product. With a perfect, tight fit to the pallet and with two trays facing forward beautifully, Ernest moved on to engineer a packaging solution for the pallet load itself.

Using DST lids, essentially a big shoe box lid, went around the shroud to take the brunt of the weight. Pallets can sit at Costco Distribution Center or have other pallet stacked on or next to them, which can raise greater weight-bearing concerns. V-board was used to protect the sides from other pallet and corrugated pads sat between each layer.

Once the pallet hits the sales floor, the shroud came off and looked great to the consumer. The single die-cut trays are flood coated with black on the inside. This reverse out, full coverage allowed for Ton Savon’s branded artwork to print perfectly on the outside.

“We work on product design, and Ernest takes care of the protection” Elhaik said. “We were good partners that way. We really relied on Ernest on the pallet layout.”

The Result

Ton Savon’s pilot launch sold out quickly. Costco wanted to take it to the next level with a substantial order of 230 pallets!

“Ernest has been so receptive and customer friendly, with high quality of customer service and great pricing,” Elhaik said. “They even came to our office. We really appreciate how customer service oriented they are, especially as we prepare for such a larger order.”

It seems we may have a thing for the French here at Ernest Packaging Solutions. From champagne to soaps and hand creams, they know how to get packaging done right. If you want your customers to say “Oo la la” at your next packaging project, contact Ernest Packaging Solutions today.