When your product is as delicate as human blood, your cold chain packaging solution better be top-rate.

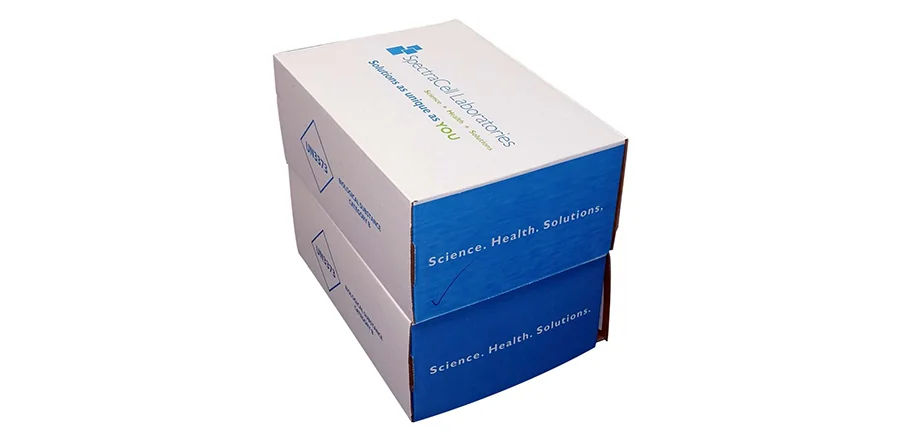

And if you’re shipping 8,000-10,000 units a month, you also want it to be cost-effective, easy for your customers to use, and maybe even recyclable. For SpectraCell, Ernest was able to strike this perfect balance for SpectraCell Laboratories, and is working toward meeting even more of the company’s end-to-end business needs.

What we can do for you

What started as a cold call has grown into a collaborative relationship with powerful bottom-line benefits. Ernest sales rep Joseph Kenworthy reached out to Houston-based SpectraCell Laboratories, Inc. in 2017, to see if he could offer them better packaging solutions. He met with the company’s vice president of operations, Kathy Boggs, and provided the 160-employee company janitorial supplies and stock packaging solutions.

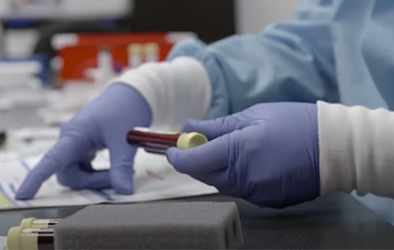

SpectraCell is a personal wellness pioneer, specializing in intracellular micronutrient and cardiometabolic testing to help prevent and manage disease. The company conducts proprietary tests in their on-site laboratory. In addition to drawing and testing blood for local patients, they receive between 350 and 400 testing kits each day from physicians around the world, from Portland to Puerto Rico. When physicians FedEx specimens back to SpectraCell for testing they must be received within two days or they have to redraw the blood, which is not only frustrating for patients, it’s costly for SpectraCell.

“We were thinking about changing our packaging because it was temperature dependent. The challenge we were facing was that the specimens were protected for breakage, but not for high or low temperatures. They have to reach us within 24 to 48 hours, or they are no good.”

Kathy Boggs

VP of Operations, SpectraCellCue the cold chain

A few months after Ernest began supplying SpectraCell, Ernest cold chain specialist Larry French paid the company a visit to discuss their temperature-dependent packaging needs and Ernest’s proprietary TempEndureTM solutions. According to Boggs, “We were thinking about changing our packaging because it was temperature dependent. The challenge we were facing was that the specimens were protected for breakage, but not for high or low temperatures. They have to reach us within 24 to 48 hours, or they are no good.”

With blood being shipped in from all over the world, it’s not uncommon for a package to sit on a truck in extreme temperatures. When this happens the blood cells can be dead by the time they reach SpectraCell’s lab, and the company isn’t able to complete the micronutrient test. And nobody’s happy when clients have to redraw blood. The Ernest team was confident they could help since the company offers some of the toughest packaging on the market to deliver protection in hostile shipping environments.

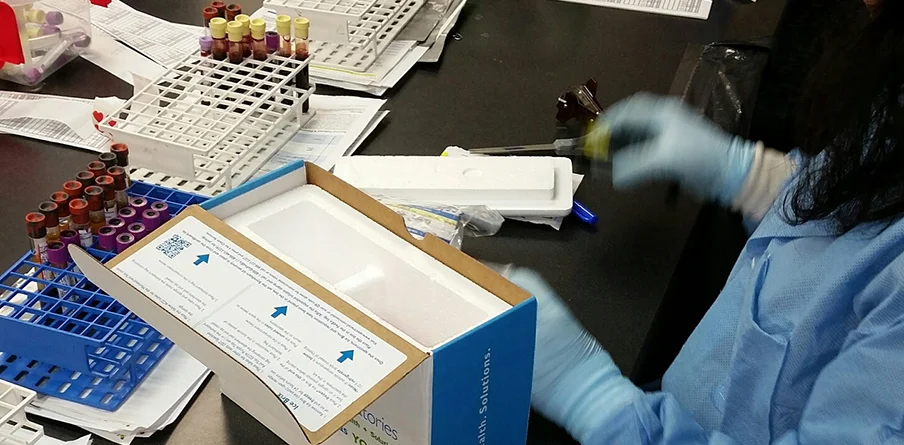

After Ernest introduced SpectraCell to TempEndure options, the key players brainstormed a new, improved specimen shipping solution. Boggs, Kenworthy, French and Ernest Houston’s GM, Eddie Canales, solved the temperature problem and more — an outer 10x6x4 box is branded with SpectraCell art so it stands out in the medical office and on the truck. It contains a 9x5x3 EPS cooler, blood vial tubes, and a custom Styrofoam insert to hold the vials and an ice brick in place during shipment. Physicians receive the package, brick in place during shipment. Physicians receive the package, which includes the tubes, a biohazard bag, the ice brick, a requisi- tion, a FedEx bag, and a printed label with simple instructions. All but the tubes, FedEx bag, and requisition come from Ernest. Once they draw the blood, physicians insert the vials and ice into the Styrofoam holder, close up the box, and place it in the FedEx bag for shipment back to Houston.

“We wanted something easy for the client to use,” says Boggs. “In addition to controlling the temperature, the new solution is more rigid so it also protects against breakage.”

The whole package is smart and savvy, and saves SpectraCell from losing specimens — and losing business. Controlling the temperature helps main- tain the integrity of the specimens for up to two days, which offers another process cost savings opportunity. And with Ernest’s just-in-time inventory management, materials are delivered to SpectraCell on an as-needed basis, saving space, costs, and headaches. Now SpectraCell can handle unex- pected spikes or lulls in their business without having to worry.

Boggs says the new solution keeps their clients much happier, too. “With some sending packages every day and some every month, losses are going to happen. But by lowering that rate we’re able to keep more clients and grow our business.” Plus, the new design reduces waste.

“Losses of 5-6% are normal in our industry, but we were experiencing higher losses — up to 10%. Now that we’re using Ernest’s solution, we have been as low as 2.5%.”

Kathy Boggs

VP of Operations, SpectraCell Labs“What I like most about Joe is that he calls on us to see if I have any problems or need anything — I don’t have to reach out to him. That’s very important to me.”

Kathy Boggs

VP of Operations, SpectraCell LabsGoing above and beyond is our normal

So what’s next for Ernest and SpectraCell? Finding new ways to use the new packaging. According to Boggs, “We are forever expanding our menu. We have another group of tests that use the same package in a different way. We’re adding on testing as we go further with the expansion of our laboratory. I’m glad to have Ernest as part of our team so we can tap into their process and packaging expertise as we grow.”

“At Ernest we’re not just about selling products. Our priority is always building solid relationships with our clients and helping them succeed any way we can,” says Kenworthy. Boggs agrees, adding, “Both the relationship and the product are important — you have to have both. I’ve met everyone at Ernest from Joe to the sales manager to [the president] Tim, and I’ve been very impressed with everyone. Ernest is a great organization to work with.”